BUSINESS INTRODUCTION

INTRODUCTION OF OUR BUSINESS MODEL

BUSINESS FLOW

DESCRIPTION OF OUR BUSINESS FLOW

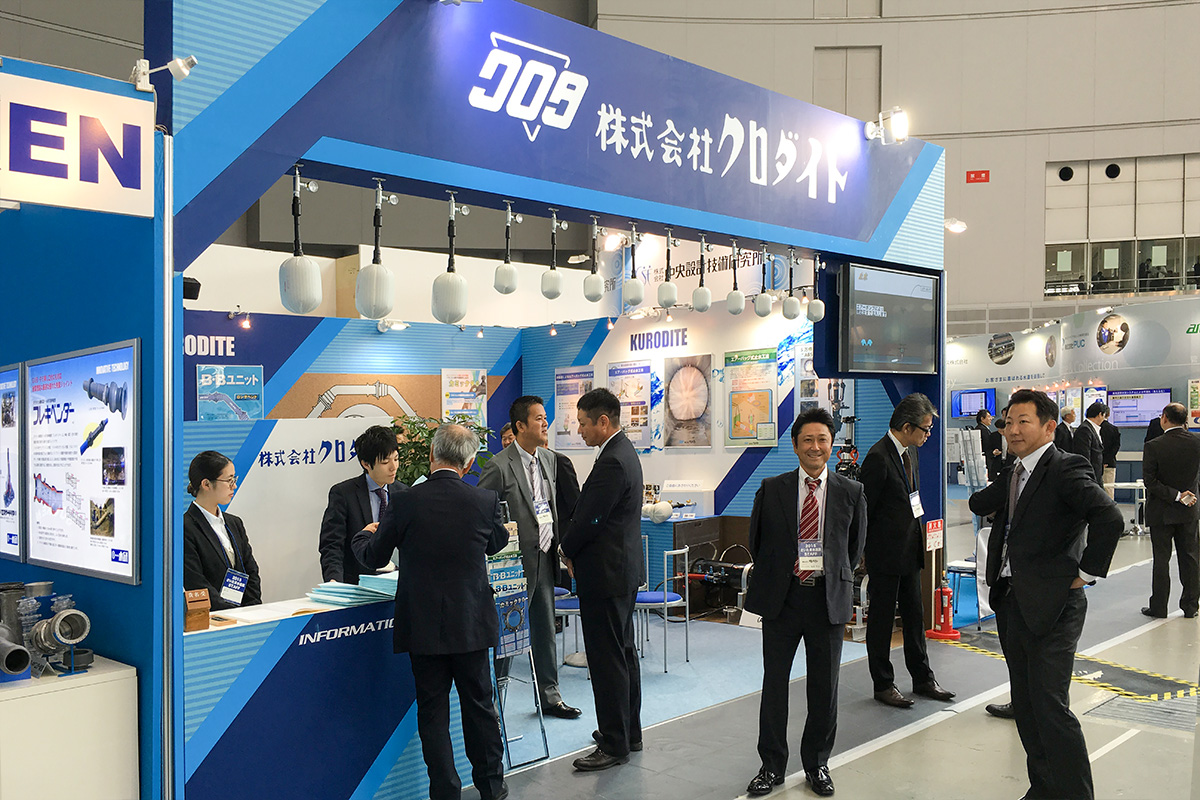

1. MARKET RESEARCH/PLANNING/PR CAMPAIGN

- Collection and analysis of market research data in and out of Japan

- Collection and analysis of technical information through collaboration between industry, government, and academia

- Target setting for products’s usage and area based on investigated needs

- Product development through companywide proposal activities

- Information exchanges with competitors as well as companies from different fields

- PR campaign through nationwide sales network

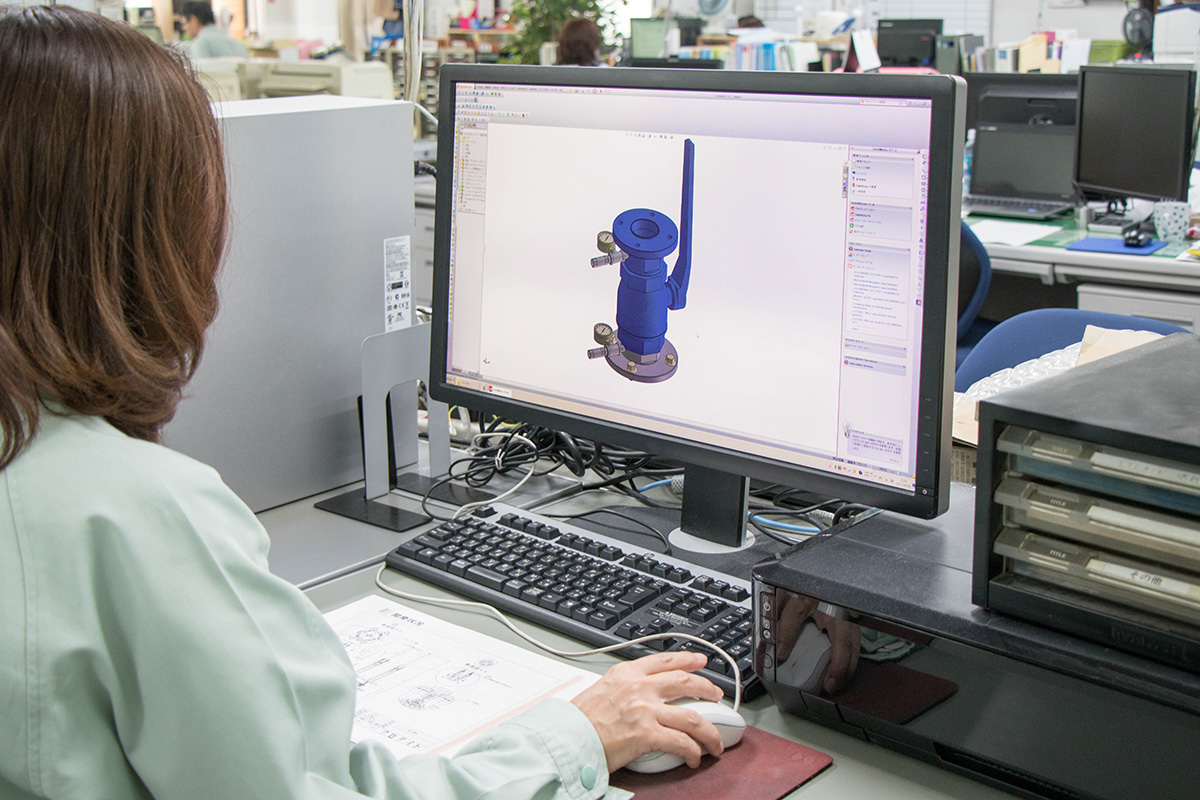

2. Design

- Design specification setting

- Collaborative product development with customers aiming for higher quality and higher functionality

- Analysis by 3D CAD simulations

- Quality verification by examination

- Planning of effective promotional materials

- Creation of sales plan with full use of nationwide sales network

- Creation of production plan to ensure high quality and high efficiency

3. PROTOTYPE AND PRE-PRODUCTION

- Process planing

- Decision making on production facilities and equipments

- Establishment of quality control standards and prehension of process capability

- Creation of quality control charts

- Establishment of inspection plans and quality assurance system

- Selection and inspection of purchased items and suppliers

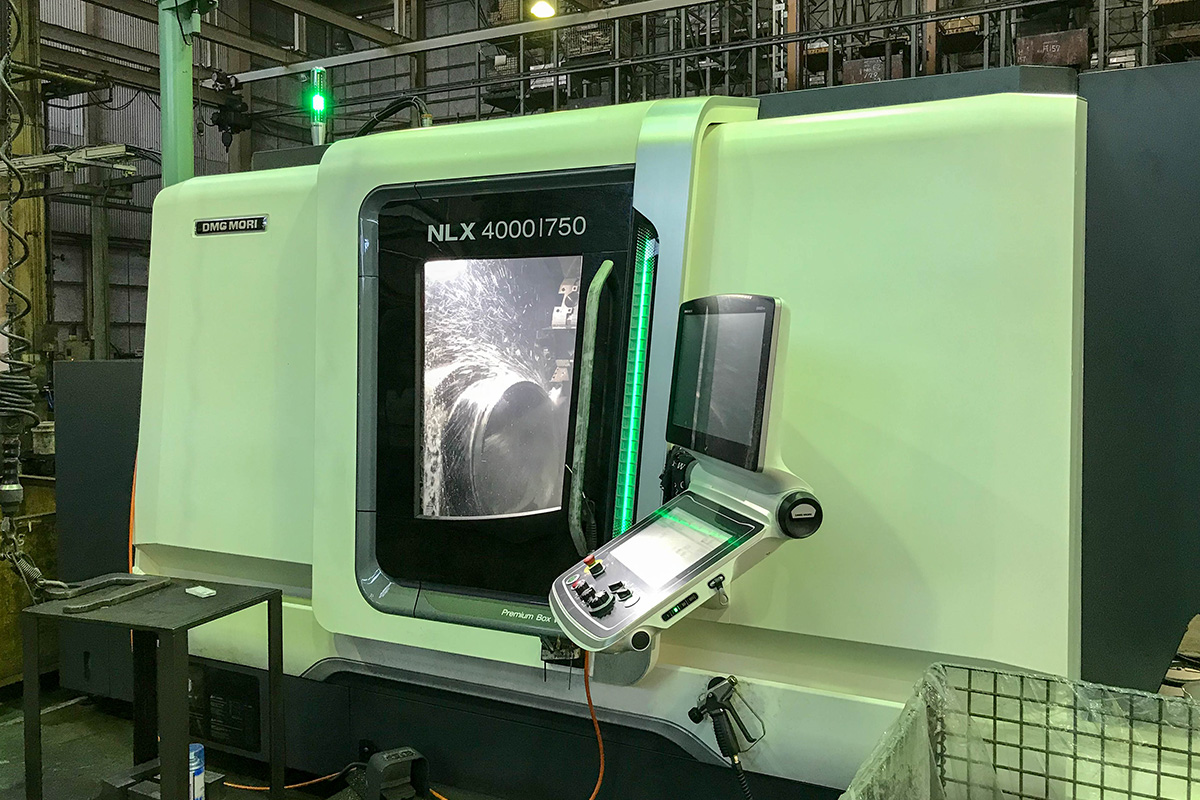

4. MACHINE PROCESSING

- Equipped with DISA230A, the world’s fastest automatic production line, and molding production line capable of casting various-sized products

- Quality control applied for every batch with inspecting devices such as quanto recorder, carbon analysis device, spheroidizing-checking device, image analysis device, etc.

5. CASTING AND FINISHING

- high quality assured finishes with the use of state-of-the-art and high-performance machines

- High-speed and high quality machining with 3D surface-machining CAM

6. INSPECTION

- Thorough quality control by various test and analysis equipment facilities

- Measurement inspection using non-contact 3-dimensional measuring machine, enabling high precision and accuracy of the products

- Reliable finishing and inspection system followed by quality control process chart

7. COATING

- Upgraded coating technology and facilities to assure long-lasting products

- High-quality coating finish provided by robot-coating facilities

9. SHIPPING INSPECTION / SHIPMENT / WARRANTY SERVICE

- Shipping inspection / shipment / warranty service

- Instruction guidance for users and dealers

- User satisfaction survey and prehension of market position

- Quality assessment

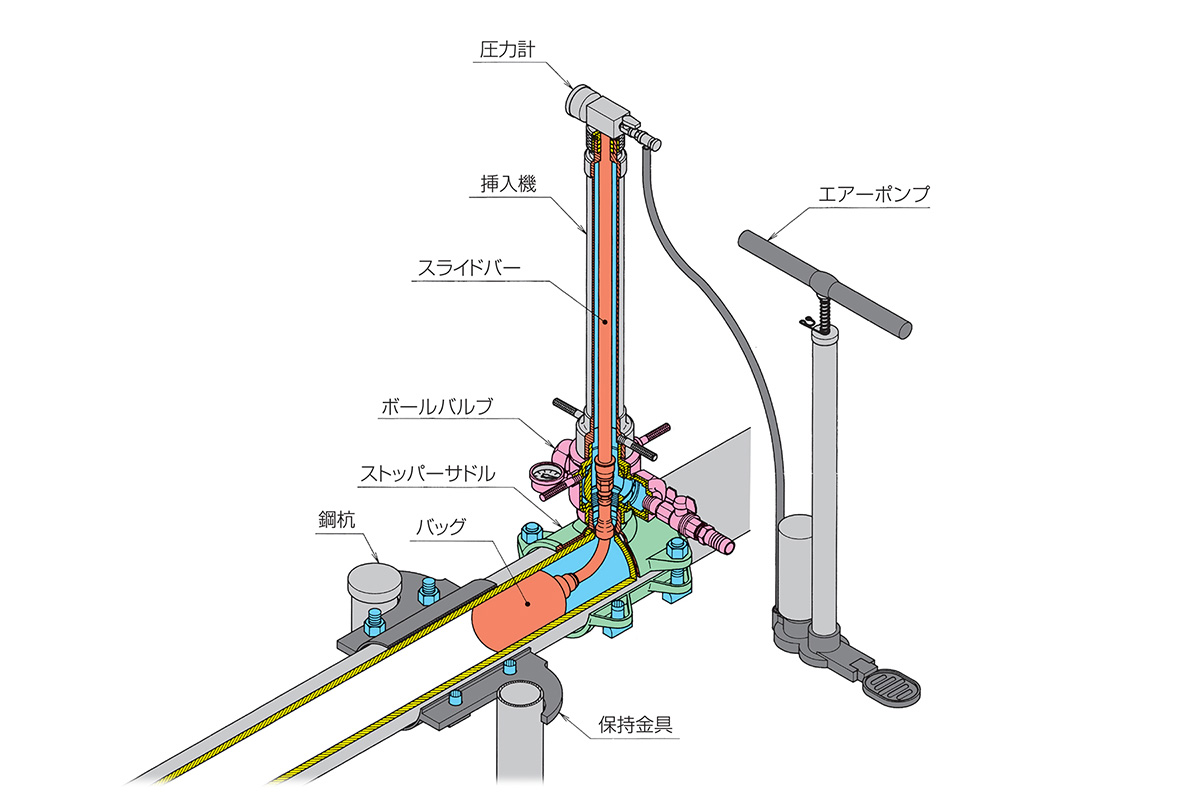

10. CONSTRUCTION

- The Air-Bag Stopper Method (ABS Method) is a method developed for temporarily shutting down water pipeline by inserting an inflated air-bag through a drilled pipe.

- Determination of production facilities and equipments

- Safe, easy, and fast construction.

- Over 50,000 construction cases across Japan.