ABS METHOD

OVERVIEW OF AIR-BAG STOPPER METHOD

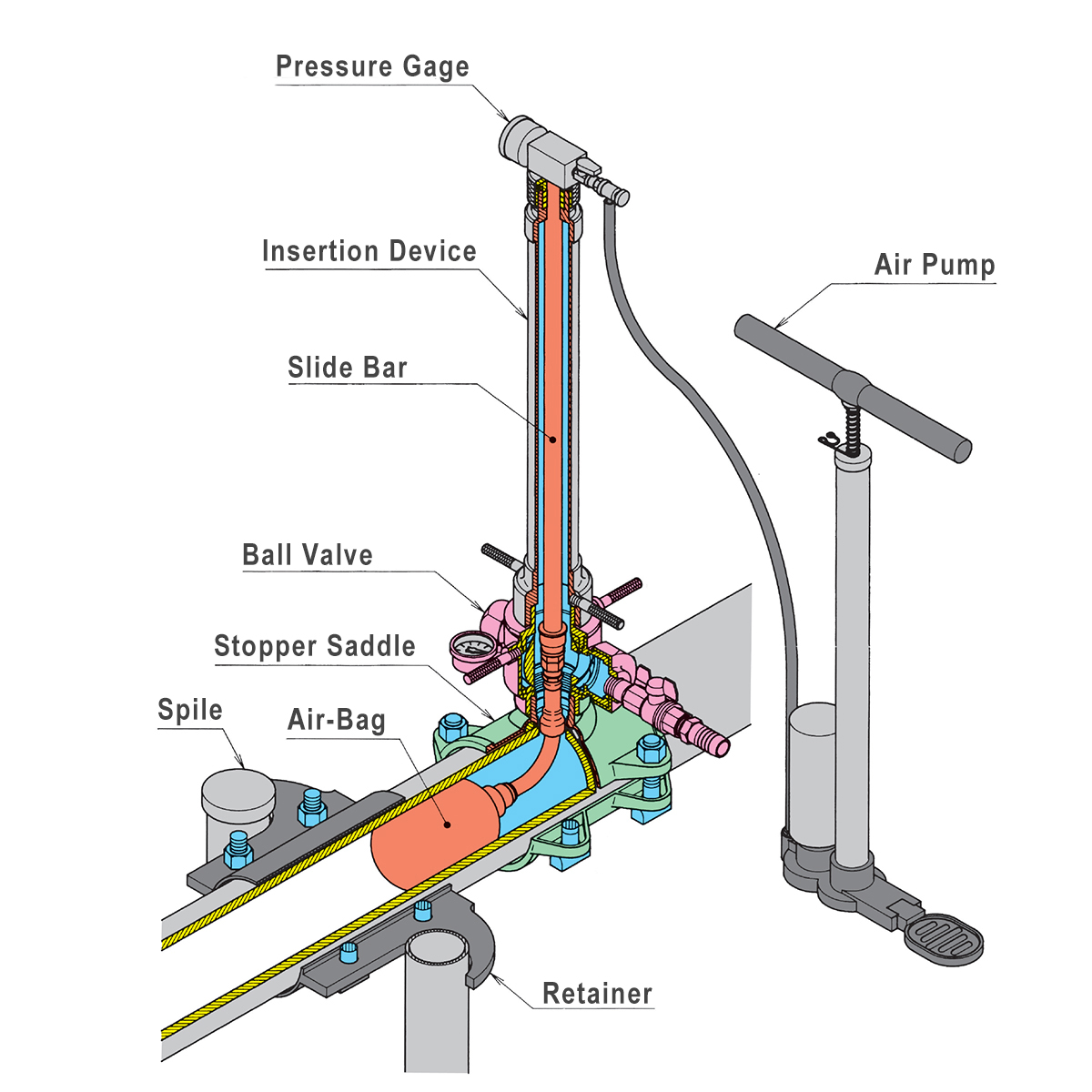

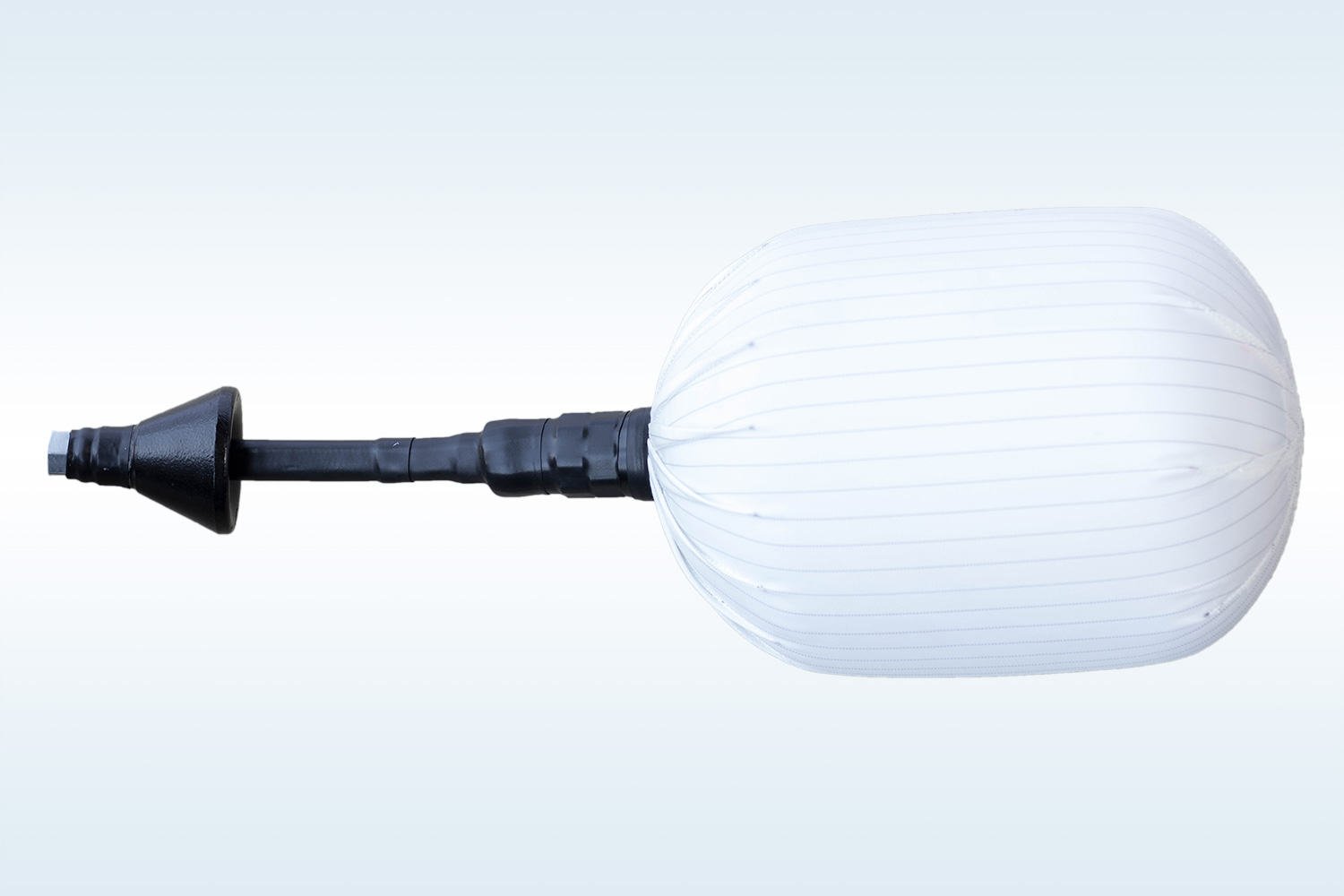

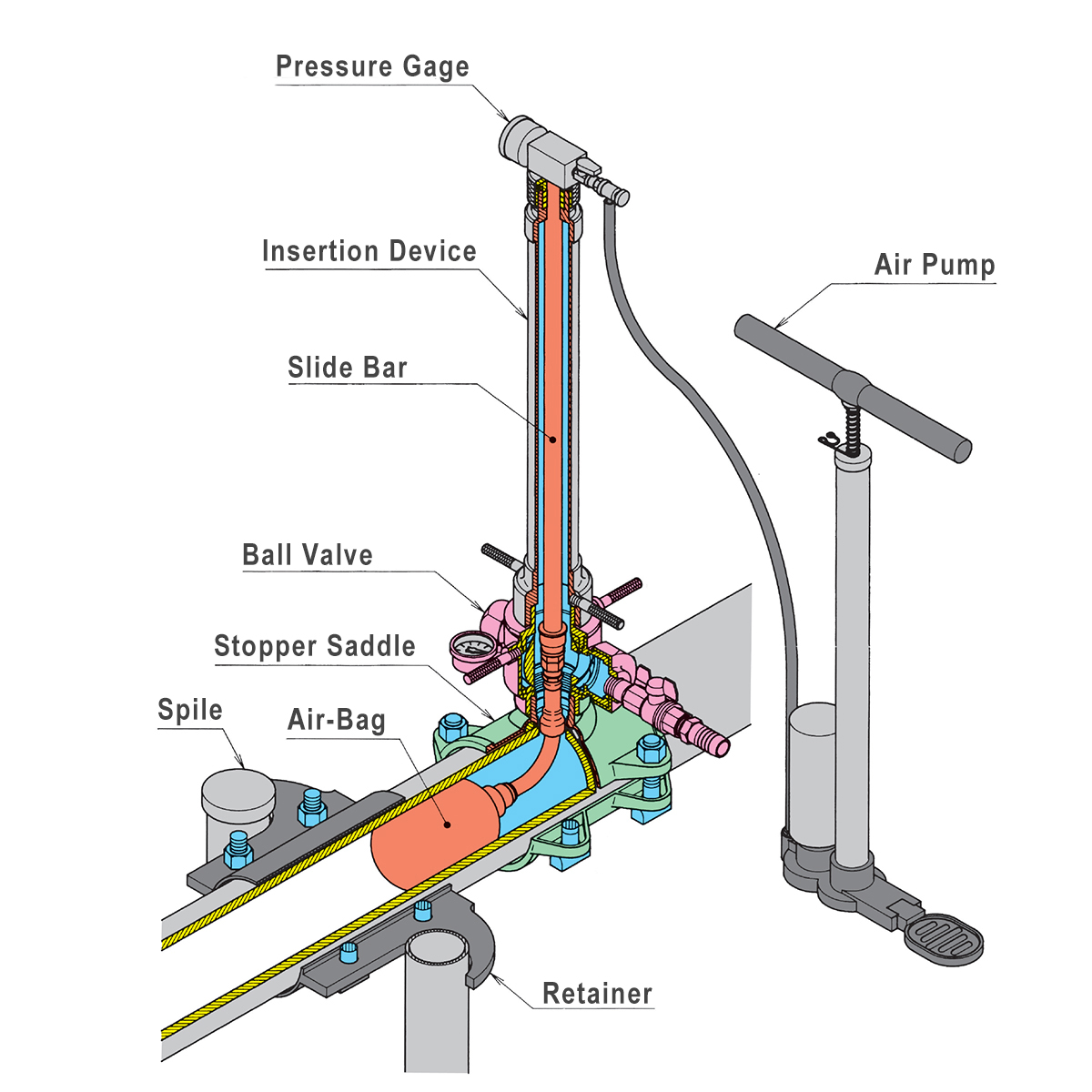

The Air-Bag Stopper Method (ABS Method) is a simple method developed for temporarily shutting down water pipeline by inserting an inflated air-bag through a drilled pipe via a saddle.

The ABS Method enables shutting down water pipeline at minimal section within a short time of period. The method also enables water suspension-free construction to carry out through a whole pipeline construction series, rather than individually separating construction phases.

There are two types of approaches for applying ABS Method, depending on the saddles;

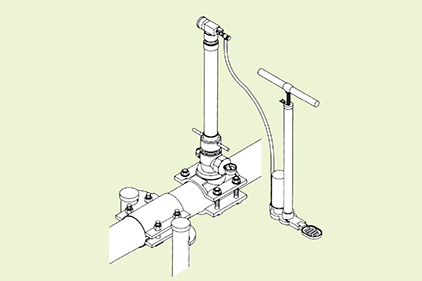

Method Type 1/With a self-developed stopper-saddle made specifically for ABS Method

Method Type 2/With commercially available ferrule with a saddle

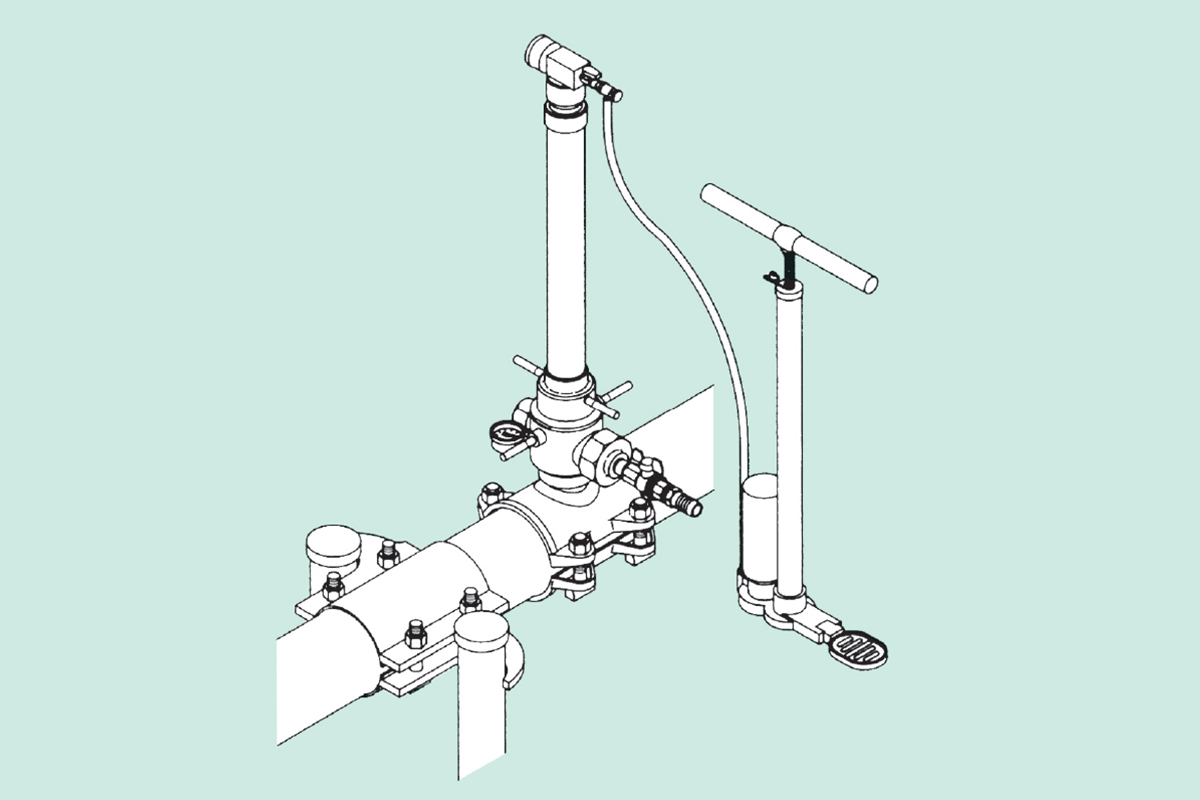

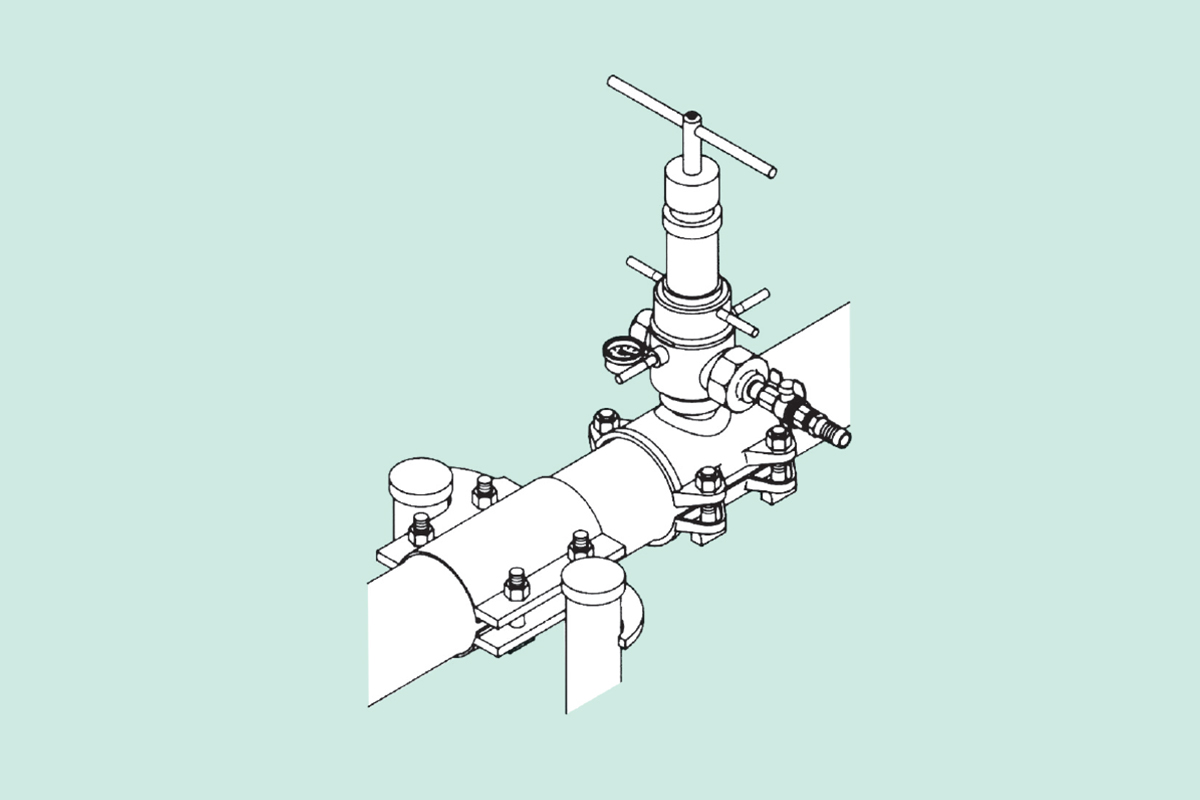

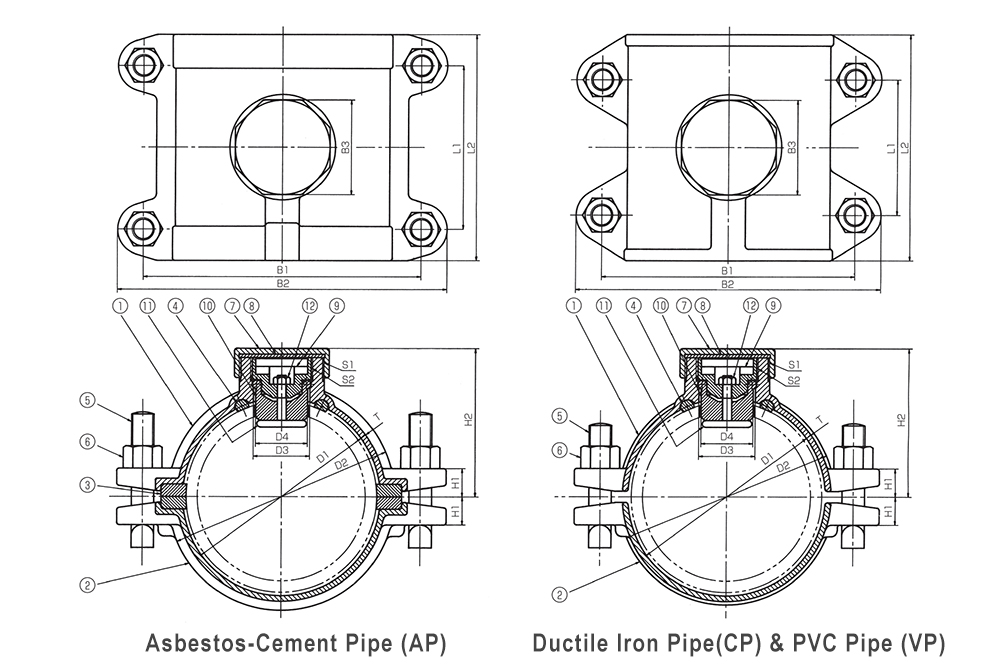

Component Image for Method Type 1

PROCEDURE

ABS CONSTRUCTION PROCEDURE

EXAMPLE WORKS

CONSTRUCTION SITES ABS METHOD WAS APPLIED

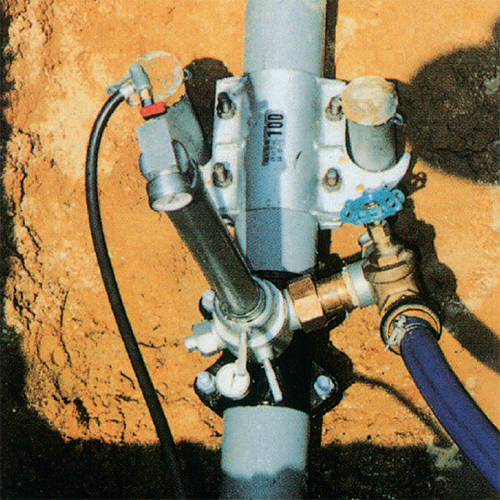

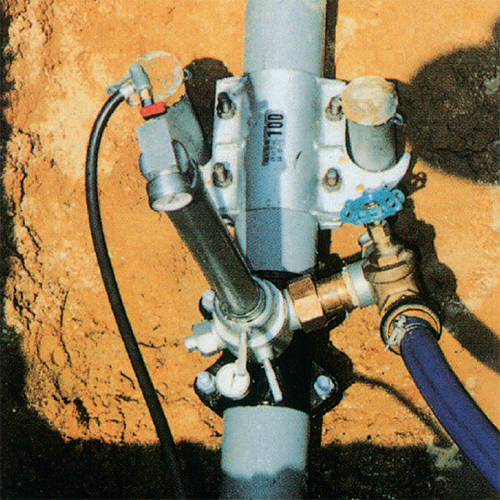

-

T-City・φ100 ductile iron pipe

PIPE LEAKAGE REPAIR

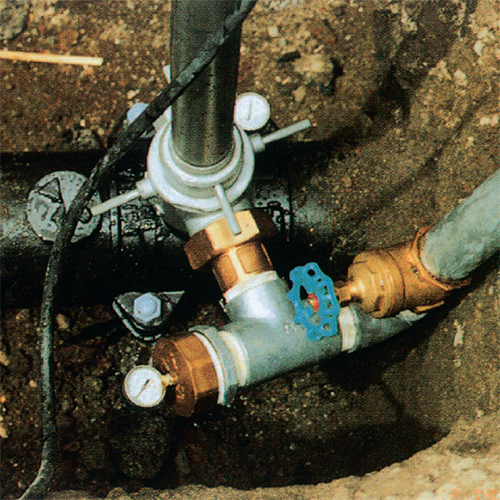

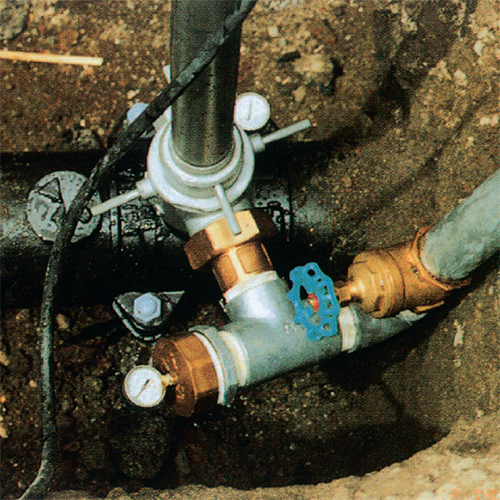

-

K-Town・φ125 ACP

PIPELINE RENEWAL

-

M-City・φ100 PVC pipe

GATE VALVE REPLACEMENT

-

T-City・φ100 ductile iron pipe

DISASTER RESORATION

-

K-CITY・φ6″ ductile iron pipe

PIPELINE RELOCATION

-

S-City・φ100 ductile iron pipe

PIPE RELOCATION

INTRODUCTORY MOVIE

AN INTRODUCTION MOVIE OF ABS METHOD

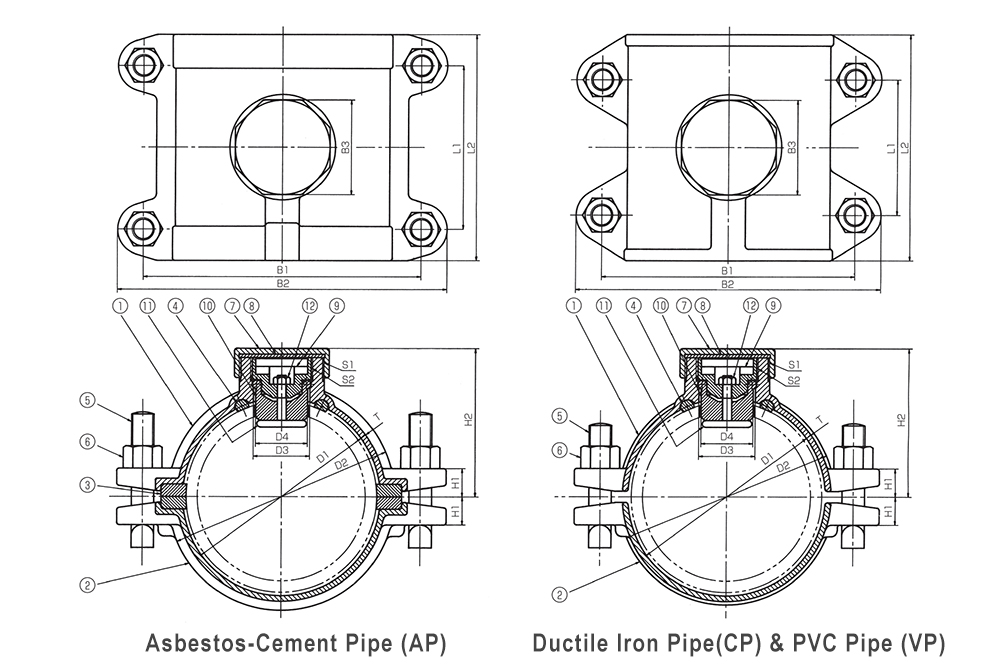

STOPPER SADDLE

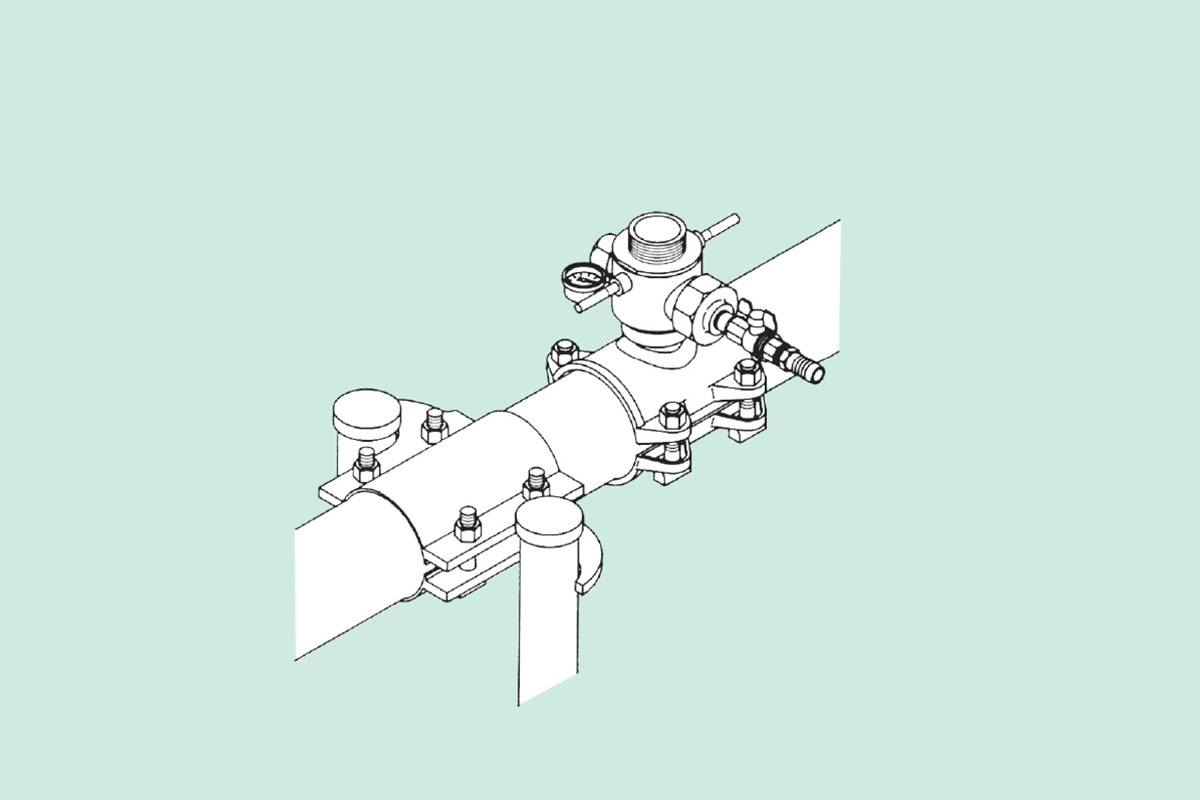

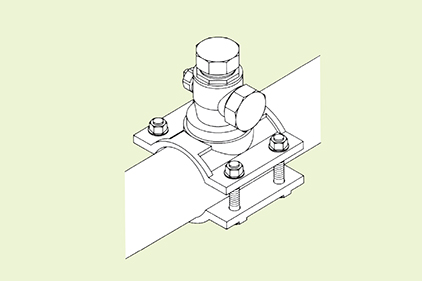

STOPPER SADDLE DESIGNED FOR ABS METHOD

FEATURES

FEATURES OF THE STOPPER SADDLE

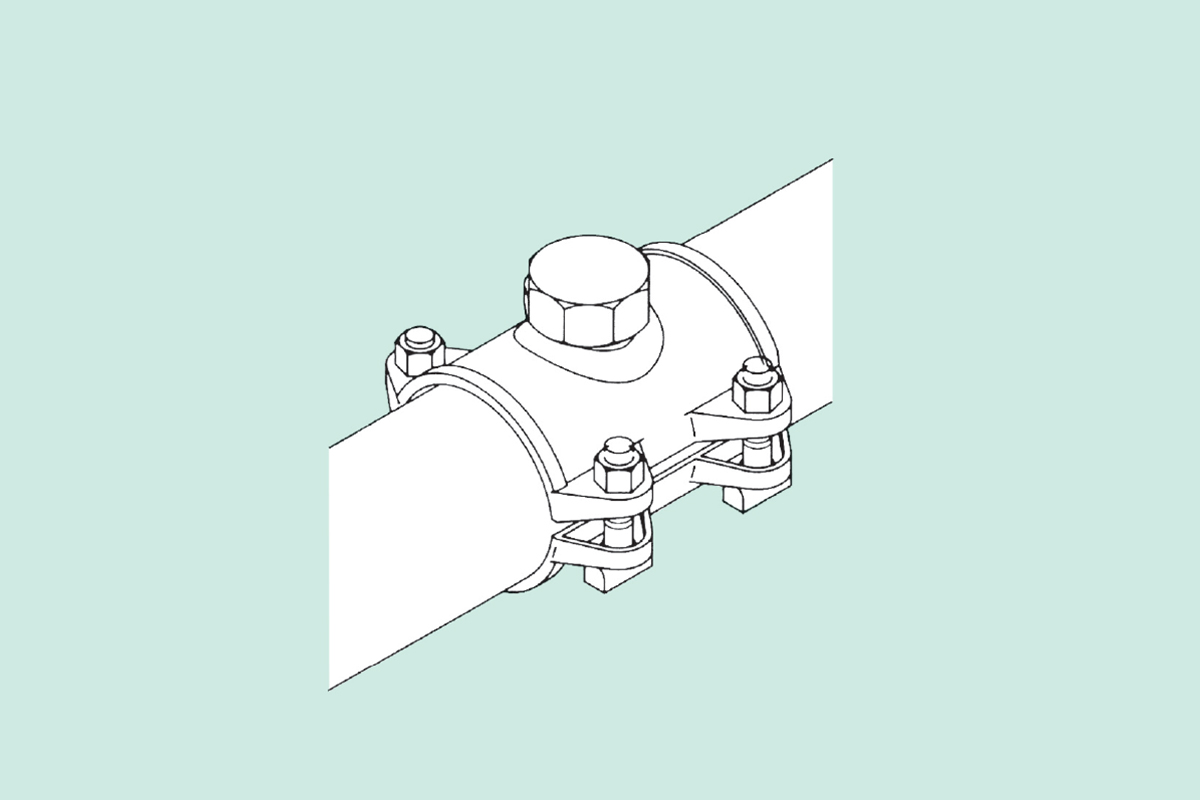

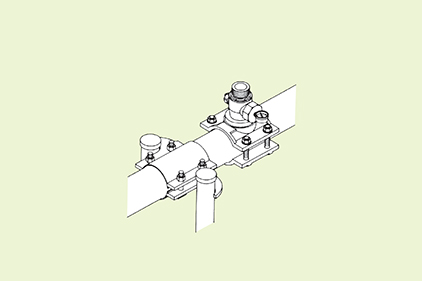

The stopper saddle is specifically designed and developed for the ABS Method.

Small protrusions/ The protrusions of the saddle is at its minimal size. Less chance of damaging when re-digging.

Anti-corrosive at hole portion/ Plug gasket will adhesively contact to the hole portion. Hence, it will prevent the chance of corrosion。

Reinforcement of ACP/ As the saddle is widely designed, inner circumferential saddle gasket further protects the pipe.

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|

| ELEMENT NAME | Saddle | Band | Saddle Gasket | Hole Gasket | T-Slot Bolt | Nut | Cover | Cover Gasket | Plug | Plug Gasket | Plug Holder | Plug Nut |

| MATERIAL | FCD 450-10 | FCD 450-10 | SBR | SBR | Alloy Ductile Iron | Alloy Ductile Iron | FCD 450-10 | SBR | Alloy Ductile Iron | SBR | Alloy Ductile Iron | SUS 304 |